myplant bio

Uniting the best of two worlds

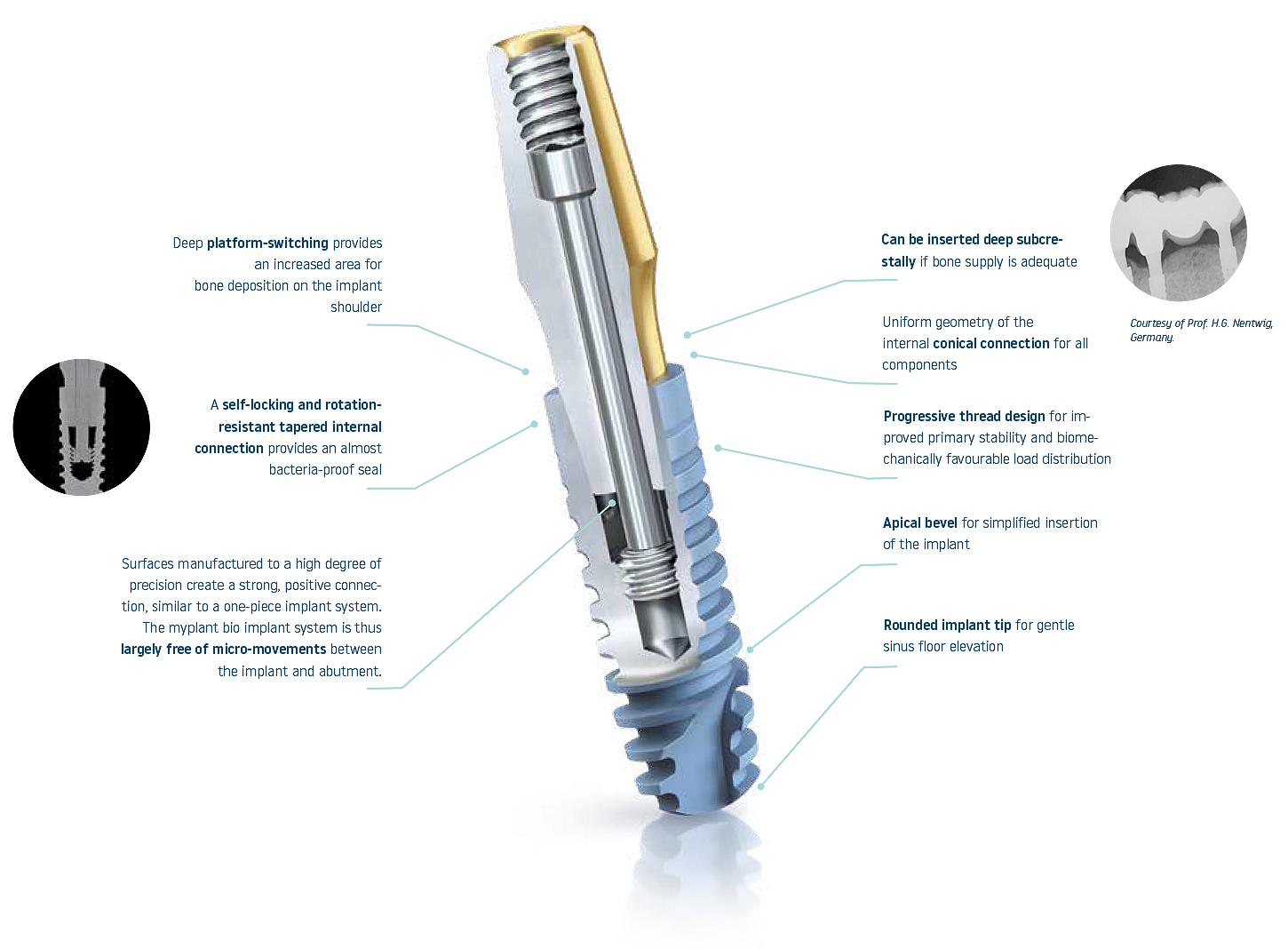

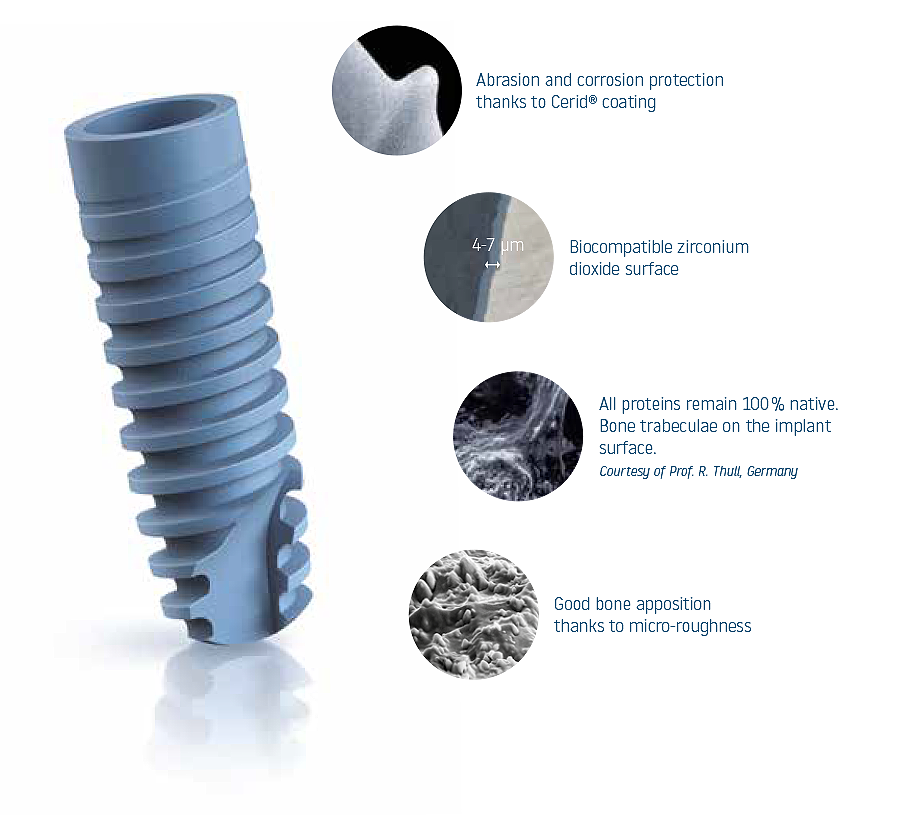

With myplant bio myplant GmbH combines the tissue-friendly properties of a ceramic implant with the technical advantages of a titanium implant.

In this process, the titanium abutment and implant are encased in a strong, biocompatible ceramic layer.

The benefits of ceramic implant surfaces, with their exceptional tissue compatibility and biocompatibility, have been known about for many years and verified by numerous studies. Using a complex multi-phase high vacuum followed by a condensation process, an abrasion-resistant ceramic layer (Cerid®) is applied to the implant and a ceramic niobium layer (Niob) to the abutment section.

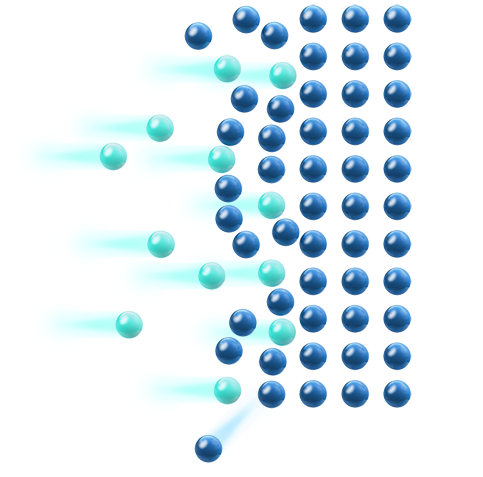

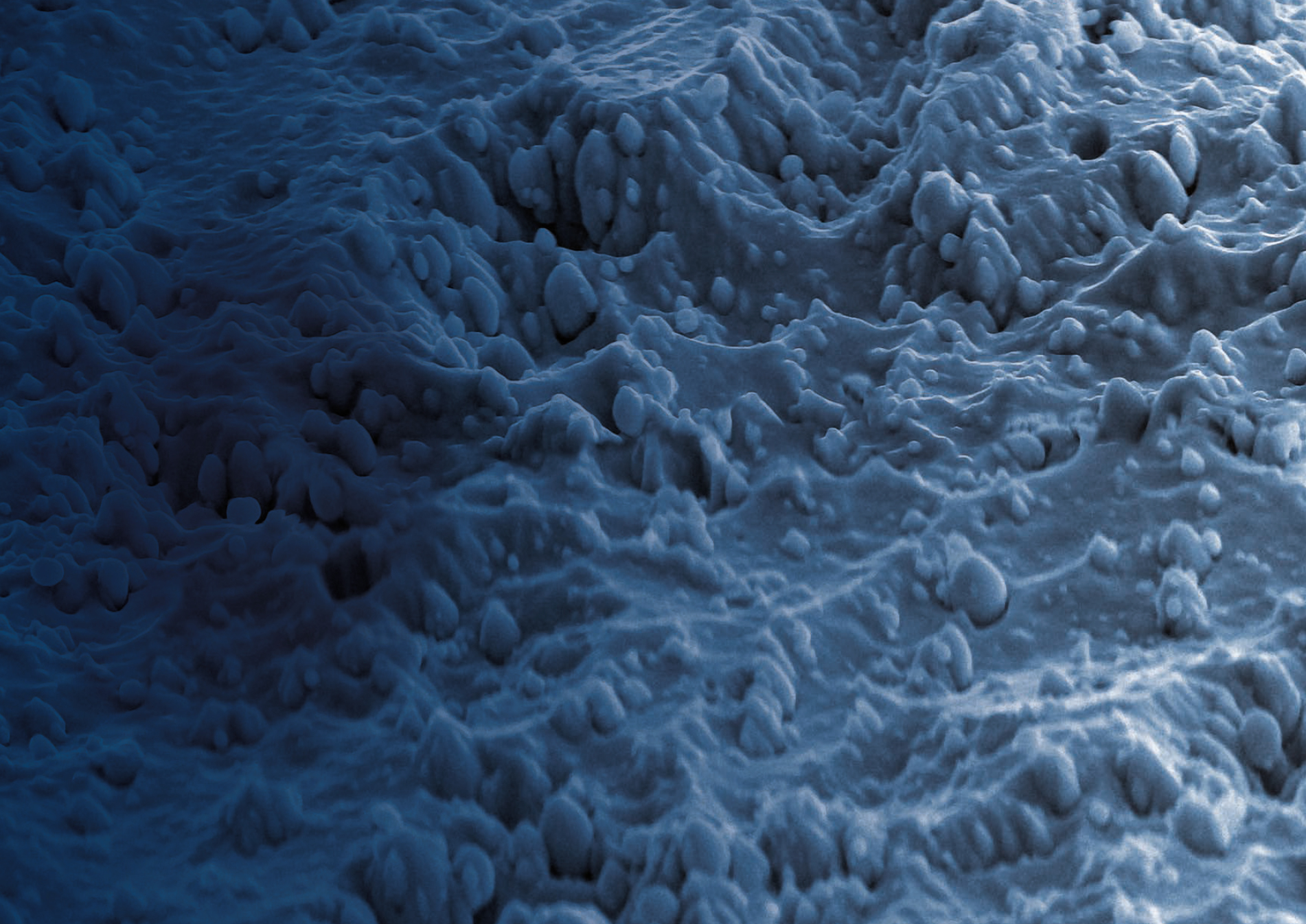

This bioengineering process, which has undergone advanced development specifically for myplant bio dental implants, involves high-energy charging of atoms, which then penetrate deep into the surface of the titanium and thereby form the abrasion- and shear-resistant titanium/ceramic composite.

The shear-resistant ceramic dioxide layer produced is approximately 4-7 micrometers thick. One of the special features of the high-strength Cerid® and niobium ceramic layer is its high biocompatibility, with an index of 1.

It is well known that mucositis is frequently a prelude to peri-implantitis, resulting in implant loss. Both Cerid® and Niob exhibit the highest chemical stability of all materials used in medical applications. This all but rules out titanium corrosion involving destruction of the passivating protective titanium layer, as can occur in the acidic environment of inflammatory gingival changes.

The Cerid®/Niob® surface technology used in

The Cerid®/Niob® surface technology used in

The smooth Niob ceramic surface features anti-plaque properties.

The smooth Niob ceramic surface features anti-plaque properties.